Church Bells

New Bells

We supply our own range of locally cast bells, up to a maximum weight of 2cwt (100kg). We can supply larger bells than this, from two different UK foundries, and also several European foundries.

A loam cast bell, designed and tuned by us, but cast in Italy.

A set of 8 locally cast bells using sand moulds.

Second Hand Bells

We keep a good range of second hand bells to suit most applications. We also regularly work with The Keltek Trust, who maintain a list of used bells which are available for transfer.

Augmentations

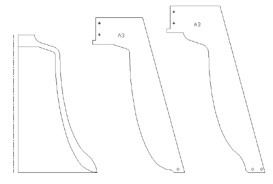

If we augment an existing peal of bells, every effort is made to ensure a perfect blend between the old bells and the new. We take profiles and metal samples of the existing bells, and design the additional bells to match. When casting new bells, we can specify the moulding process and materials to be used, all of which can have impact on the tone of the bell. Drawings for specially designed moulding gauges.

Drawings for specially designed moulding gauges.

Conservation of Existing Bells

Cracked bells can be repaired by specialist welding techniques. Original wrought iron cast-in crown staples can corrode and build up pressure on the surrounding bell metal. This is the most common cause of bells becoming cracked. Cast-in crown staples can be carefully extracted to reduce this risk.

Bell Tuning

All of our bell tuning is undertaken in-house. Existing bells and peals can be re-tuned to enhance their tone, power and musicality. We use the latest tuning techniques, including (where applicable) the tuning of old bells on the outsides of their soundbows, in order to maximize the improvement to the partial tones, giving results which would not be possible with internal tuning alone. Because we don’t cast large bells ourselves, there is no commercial advantage in not aiming to get the best possible results, in the tuning of existing bells. Analysis software running Fast Fourier Transforms used in conjunction with a stroboscopic tuner allows for a high accuracy of tuning to a suitable authentic temperament. Our main tuning lathe can accommodate bells of up to about 21cwt and we have access to a larger lathe which will tune up to a three-ton bell. The results of our tuning work, speak for themselves.

Bellframes

New bellframes are designed using CAD and are using cast iron, steel or hardwood. All our steelwork is hot-dip galvanized in line with BS EN ISO 1461: 1999.

We also carry out repairs, strengthening, alterations or extensions to existing bellframes.

Bell Fittings

Our change ringing fittings are produced to both modern and traditional designs, and are made from the finest available materials. We also carry out repairs to existing fittings as necessary.

New ringing fittings include:

Headstocks - We supply both conventional and canon-retaining headstocks made from steel, cast iron or hardwood. Details of our headstocks are listed below:

Cast Iron Conventional Headstocks.

Cast Iron Headstocks are generally considered to be the 'Rolls Royce' option for bells with no canons.

Having supplied and fitted numerous examples made by sub-contractors in our 27 year history, we have over the past 5 years, introduced an entirely new range of our own cast-iron headstocks.

Having studied numerous examples of cast iron headstocks produced by 5 other bell foundries/hangers (produced over a period of 120 years), we have combined some design and sizing features with the use of Spheroidal Graphite 'ductile' Cast Iron to produce a completely new range of cast iron headstocks. Our casting patterns are adjustable to make bespoke headstocks to suit most bells and bell frames. Our turned steel gudgeons are locked into Morse Taper sockets which have been machined in true alignment. This maximises the level of contact between the two materials and reduces the risk of breakages/play associated with steeper tapers or cast-in gudgeons. It also allows for broken or defective gudgeons to be replaced if ever required. Clapper adjustment screws for the setting and subsequent adjustment of even clappering are a feature of all headstocks in this range. Other features include a bell bolt-pad which can be drilled in different locations (including through the main body of the headstock) to pick up on existing bell bolt holes and a side-mounted stay.

The above photographs are of cast iron headstocks supplied to Dordrecht (Grote Kerk) and Tewkesbury Abbey.

Fabricated Steel Conventional Headstocks.

This type of headstock is a cheaper alternative to cast iron headstock and is ideally suited to lighter bells. Fabricated headstocks give greater scope for wheel and stay positions, which may be useful if bells are being installed in an existing bellframe. This type of headstock is made bespoke to suit the individual needs of a particular bell (which may be an unusual size or weight) to achieve a particular swing time, to align with other bells in a ringing peal. Features are largely similar to our cast iron headstocks but the steel gudgeons are welded into place and are turned between centres following fabrication.

Fabricated Steel Canon Retaining Headstocks.

The basic design for this type of canon retaining headstock was originally conceived by The Whitechapel Bell Foundry in the mid 1990's, and is generally considered to give the best performance characteristics, particularly when combined with other bells which do not have canons. We have developed our own range of canon retaining headstocks which are largely based on this same design. This type of headstock gives good visibility of preserved canons and allows for ultimate flexibility for turning a bell to allow the clapper to strike an unworn face of the soundbow. Whilst this type of headstock precludes the fitting of clapper adjustment screws, there is usually scope for the fitting of an adjustable crown staple to achieve the same level of adjustment. Steel gudgeons are welded into place and are turned between centres following fabrication.

Timber Headstocks.

This type of headstock is most often supplied to conservation based projects, or those which need to be aesthetically pleasing.

Bell Wheels - Existing bell wheels can be restored or re-rimmed. Our new bell wheels are made from finest quality hardwood. All fixings used in our wheels are of stainless steel.

A bell wheel being re-rimmed with all new hardwood soling, shrouds and stainless steel fixings.

Main Axis Bearings - High quality self-aligning ball or roller bearings, in cast iron housings, are fitted to all of our installations. Our brands include SKF, RHP, FAG and Timken. Existing bearings can be serviced or refurbished.

Clappers - The material, profile and weight of a clapper can have a large effect on the sound of a bell.

Many towers still retain their original wrought iron clappers. These can be overhauled, heated and twist turned to present an unworn face of the clapper ball to the strike, and annealed to relieve and stresses.

New clappers are made from spheroidal graphite (ductile) cast iron and are fully machined (bespoke) to suit each individual bell.

A new spheroidal graphite cast iron clapper, in the process of being machined.

Our clappers are bushed with PTFE impregnated tufnol, and we fit grease applicators as standard.

We endeavor to keep a stock of clappers of all sizes, to enable us to provide a fast clapper replacement service.

We replace leather baldrick type clapper linings.

An original wrought iron clapper being twist turned, to present an unworn face of the ball to the strike. An annealing process follows this.

Please note - We do not rebuild (or reface) worn clappers with weld and grind them back to their original profiles. No matter what you do to the welded surface, it always remains significantly harder (in some cases, harder than bell metal) and more abrasive than the original wrought iron surface. This causes accelerated wear to the bell.

Crown Staples - Independent crown staples can be made from cast iron or steel, and are fitted with high tensile steel pivot pins. Adjustable crown staples can be fitted to bells with canon retaining headstocks, to enable the bell to be adjusted and set for even striking.

Roller Boxes - Our roller boxes are made of hardwood and are fitted with hard wearing cast nylon or turned hardwood sheaves. All of our rollers are mounted on twin ball races with spacing tubes to eliminate side-play. Standard roller boxes are available in both side or floor mounted varieties and are usually available off the shelf. Existing roller boxes can also be replicated. Our pulleys and bearings are made to be interchangeable with the Whitechapel standard sizes.

Double pulley unit with cast Nylon Sheaves.

Double pulley unit with hardwood sheaves.

Stays, Sliders & Runner Gear - Our stays and sliders are manufactured from finest quality air-dried ash. Our sliders are steam bent and come in different lengths. Standard stays and sliders are kept in stock, and nonstandard items can generally be supplied at short notice. Our runner boards are made of hardwood and have adjustable stops.

Rope Bosses and Rope Guides - We supply rope bosses in either hardwood or turned cast iron, and these are designed to reduce rope noise to an absolute minimum. Existing rope bosses can be replicated. Our rope guide frames are designed to keep rope noise to a minimum, and to look aesthetically pleasing.

Machined cast-iron rope boss.

Bellropes - We repair traditional bellropes on our purpose built rope-walk. We also supply new bellropes with a choice of top ends and sally colours.

Ropes being hand wound on our own rope-walk.

Bellhanging

All dismantling and installation work is carried out by our highly experienced team of bellhangers. All of our lifting-gear/handling equipment is regularly inspected, certificated and insured.

Setting up and commissioning

Every effort is made to ensure that our work produces the best possible results. Every bell is set up for the correct depth of set at both handstroke and backstroke and set for even striking using our laser activated timing meter. We feel that post installation care is of the greatest importance, and our staff return to our projects after 1 year to check and service the installations.

We supply new chimes of bells and restore bells hung for both stationary and swing chiming. Bells hung for stationary chiming can be fitted with our own design of trigger-action, chiming clapper. This method of chiming prevents the clapper being held in contact with the bell allowing it to freely resonate after the strike. Our trigger-action, chiming clappers can be used in conjunction with an Ellacombe type console or by a bellrope with a sally. We also build and supply trigger-action Ellacombe type hammers for use in conjunction with swinging bells. Existing Ellacombe chiming hammers can be upgraded to Trigger Action Status.

Automated systems and controller units are also available.

Two bells rehung for stationary chiming bells (Llanstadwell, Pembrokeshire).

Turret bells

We supply new and also refurbish existing turret bells. New fittings can be made to modern and traditional designs using hardwood and either galvanized or stainless steel. Our turret bell installations are designed to be maintenance free, as most are inaccessible without scaffolding.

A turret bell hung with traditional fittings.

A turret bell with modern fittings.

Associated Building Works and Joinery

This most often involves cutting pockets in tower walls to accept new beams, casting level concrete pad stones and subsequent infill after beams have been assembled in position.

Joinery may include constructing trap doors to enable bells and materials to be lowered through tower floors, or the construction of new floors and ceilings.

We strongly suggest that when building work ancient buildings is required, that it's undertaken by a fully accredited conservation building firm. It is essential that those involved have full respect for the buildings in which they are working, a comprehensive understanding of the structural engineering aspects, together with the mix of construction materials that are often involved. We urge people to beware of “all included” packages where works may end up being undertaken by inexperienced, non-accredited individuals/sub-contractors.

We are happy to work with a nominated local contractors or we can recommend suitable building firms, joiners or registered electricians.

Sound Management and Internal Acoustics

We design and install external sound management systems which can be operated both manually or remotely. We can also advise or undertake on modifications to internal acoustics.

Access Ladders and Platforms etc

We can design and provide full access ladders and platforms to give safe and effective access to any part of the tower envelope.

Belfry Servicing and Service Contracts

We offer belfry inspection and servicing visits on regular or "as requested" basis.

Our belfry servicing/maintenance visits include:

- A visual inspection of the whole bell installation, checking for defects.

- Bells are checked for cracks and wear at the strike points.

- All fixings are checked for tightness.

- Moving parts (main axis bearings, clappers and rollers) are checked for wear and are lubricated if possible (without complete dismantling) or indeed, as required.

- Stays, sliders and bellropes are checked for damage/wear.

- Simple rope repairs and adjustments can be undertaken on the spot.

- Bells can be checked and adjusted for even striking, using our laser activated meter at additional cost.

- We also encourage the local ringers/steeple keepers to join us on our service inspection, and give advice on regular upkeep etc.

- A short report of our findings is submitted along with our invoice.

- If we discover any required work (over and above that included within our maintenance inspection) we can supply a free (no obligation) quotation.

Please contact us for further information and prices.